Machine screw size charts are essential tools for selecting the right screws, ensuring compatibility and safety in machinery. They provide standardized dimensions, thread specifications, and material options.

These charts help manufacturers and engineers quickly identify screw sizes, drill sizes, and torque requirements, streamlining production and assembly processes. They are vital for maintaining precision and efficiency.

By referencing these charts, professionals can ensure proper fitment, avoid assembly issues, and comply with industry standards, making them indispensable in modern manufacturing and design workflows.

1.1 Importance of Screw Size Charts in Machinery

Screw size charts are critical for ensuring proper screw selection, preventing assembly errors, and maintaining machinery performance. They provide precise measurements, thread specifications, and material compatibility, essential for safe and efficient operations. By adhering to these charts, manufacturers avoid fastener failures and ensure compliance with industry standards like ASME B1.1, promoting reliability and consistency in mechanical systems.

1.2 Overview of Machine Screw Size Standards

Machine screw size standards, like ASME B1.1, define specifications for screw dimensions, threads, and materials. These standards ensure consistency across manufacturers, covering major and minor diameters, thread pitches, and head styles. They also provide guidelines for drill sizes and torque requirements, facilitating accurate screw selection. Adhering to these standards ensures compatibility and reliability in various industrial applications.

Understanding Machine Screw Measurements

Machine screw measurements include major diameter, minor diameter, thread pitch, and threads per inch. These dimensions ensure proper fitment and functionality, as detailed in screw size charts.

2.1 Major Diameter and Minor Diameter

The major diameter is the largest diameter of the screw thread, while the minor diameter is the smallest. These measurements are critical for ensuring proper thread engagement and preventing slip. As shown in screw size charts, precise tolerances are maintained to guarantee compatibility with mating parts and avoid assembly issues. These dimensions are non-negotiable for structural integrity and reliability.

2.2 Thread Pitch and Threads Per Inch

Thread pitch refers to the distance between consecutive threads, while threads per inch (TPI) measures thread density. These specifications ensure proper mating of screws with threaded holes. Screw size charts provide exact pitch and TPI values, enabling precise selection for applications. Accurate thread pitch and TPI are crucial for load-bearing capacity, durability, and preventing thread stripping. Proper alignment ensures optimal performance and longevity in mechanical assemblies.

Types of Machine Screws

Machine screws come in various types, including hex, socket, and slotted, each designed for specific applications. Hex screws offer high torque, while socket screws ensure secure fastening.

- Hex machine screws provide superior torque resistance.

- Socket machine screws feature a recessed drive system for security.

3.1 Hex Machine Screws

Hex machine screws are widely used for their durability and ease of installation. They feature a hexagonal head, allowing for high torque applications. Available in various sizes, they are ideal for industrial and automotive uses.

- Common sizes include 1/4, 5/16, and 3/8 diameters.

- They are often used in heavy-duty applications due to their strength.

- Printable PDF charts provide precise dimensions and specifications.

3.2 Socket Machine Screws

Socket machine screws are designed with a recessed socket drive, offering easy installation and torque transfer. They are ideal for applications requiring high strength and low profile.

- Common sizes include 5/16 and 1/2 diameters.

- Available in metric sizes like M3 and M4.

- Popular for use in machinery and electronics.

Materials and Finishes for Machine Screws

Machine screws are crafted from durable materials like stainless steel and carbon steel, ensuring strength and resistance to corrosion. Common finishes include zinc plating and chromate coating, enhancing longevity and performance.

4.1 Stainless Steel vs. Carbon Steel

Stainless steel screws offer superior corrosion resistance and durability, making them ideal for harsh environments. Carbon steel screws are stronger and more cost-effective but lack the corrosion-resistance of stainless steel. Both materials are widely used in machinery, with stainless steel preferred for outdoor or high-moisture applications and carbon steel for general-purpose assembly. The choice depends on the application’s environmental and load requirements.

4.2 Common Finishes and Coatings

Common finishes for machine screws include zinc plating, chrome plating, and phosphate coatings, enhancing durability and corrosion resistance. Specialty coatings like anodizing for aluminum screws improve surface hardness and provide insulation. These finishes protect screws from environmental factors, ensuring long-term performance. The choice of coating depends on the application, with options like hot-dip galvanizing offering superior rust protection for outdoor use. Proper finishing ensures optimal performance and longevity in various industrial settings.

Installation Guidelines

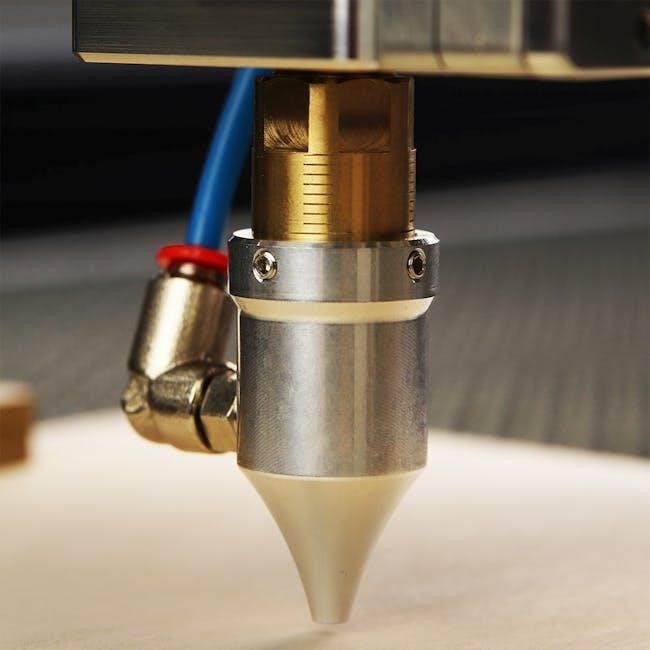

Proper installation involves using correct tap and clearance drills, ensuring screws fit securely. Torque specifications must be followed to avoid damage. Always consult manufacturer guidelines for specific applications.

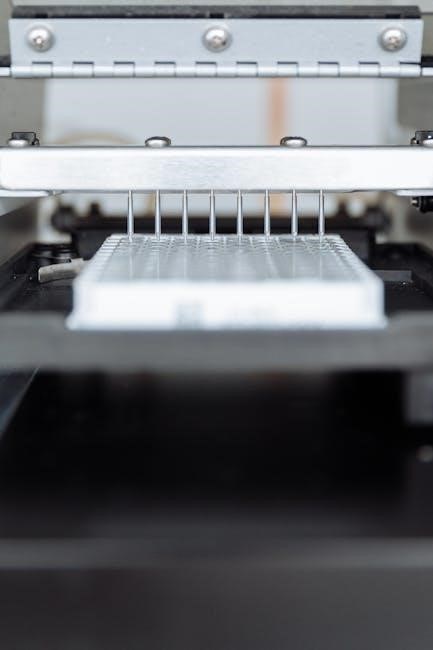

5.1 Tap and Clearance Drill Sizes

Tap and clearance drill sizes are critical for proper screw installation. The tap drill creates the thread, while the clearance drill ensures the screw fits without binding. Using the correct drill sizes, as specified in charts, prevents damage and ensures a secure fit. Proper alignment and material considerations are also essential for optimal results. Always refer to the chart for precise measurements.

5.2 Torque and Tension Specifications

Torque and tension specifications are vital for ensuring proper screw installation. These values vary based on screw size, material, and thread type. Exceeding recommended torque can damage threads or strip screws, while insufficient torque may lead to loose connections. Always consult the chart for precise torque and tension limits to achieve optimal performance and material strength. Proper techniques prevent failure and ensure long-term reliability.

Common Applications of Machine Screws

Machine screws are widely used in industrial machinery, automotive, aerospace, electronics, and construction. They provide structural support and durability in assemblies, ensuring reliable performance across diverse industries.

6.1 Industrial Machinery

Machine screws are integral to industrial machinery, ensuring secure connections and durability. They are used in pumps, motors, and heavy equipment, providing structural integrity and resistance to wear. Their standardized sizes, as per charts, enable compatibility across machinery components, simplifying assembly and maintenance. Proper sizing ensures efficient operation and longevity in demanding environments.

6.2 Automotive and Aerospace

Machine screws play a crucial role in automotive and aerospace industries, where precision and reliability are paramount. They are used in engine components, chassis, and aircraft structures, ensuring safety and durability. Their standardized sizes, detailed in charts, enable precise assembly and compliance with stringent industry regulations, minimizing risks and enhancing performance in high-stress environments.

How to Read a Machine Screw Size Chart

Machine screw size charts list dimensions, thread pitch, and drill sizes. Locate the screw size, then find the major diameter, threads per inch, and recommended drill sizes.

7.1 Interpreting Screw Size Tables

Interpreting screw size tables involves identifying key dimensions such as major diameter, threads per inch, and minor diameter. These tables also specify tap and clearance drill sizes, essential for proper installation. Ensure the screw size matches the application requirements by cross-referencing the chart’s data with the project’s specifications. Accuracy is crucial for optimal performance and safety.

7.2 Matching Screws to Specific Applications

Matching screws to specific applications requires careful consideration of material, size, and thread specifications. Use the chart to select screws that align with the application’s demands, such as load-bearing capacity or environmental conditions. Ensure the chosen screw material, like stainless steel or carbon steel, suits the environment. Proper alignment with the application ensures reliability, performance, and longevity, avoiding potential failures or inefficiencies.

Resources and Downloads

Access downloadable PDF charts for US machine screw sizes, including hex nut dimensions and thread specifications. Utilize online tools for precise size calculations and material compatibility checks.

Visit trusted sources like Albany County Fasteners for comprehensive guides and printable resources to streamline your screw selection process efficiently.

8.1 Printable PDF Charts

Printable PDF charts for US machine screw sizes are widely available, offering detailed dimensions and standards. Ensure accuracy by printing to actual size without scaling and verifying measurements using the embedded ruler.

These charts include hex nut sizes, thread dimensions, and material specifications, providing a comprehensive guide for engineers and manufacturers. Download from trusted sources like Albany County Fasteners for reliable data.

8.2 Online Tools for Size Calculations

Online tools simplify machine screw size calculations, offering instant access to tap drill sizes, thread dimensions, and torque specifications. These tools ensure precise compatibility with materials like stainless steel and aluminum.

Utilize calculators from trusted sources like Albany County Fasteners to determine exact drill sizes and thread specifications, enhancing efficiency in manufacturing and assembly processes.

Machine screw size charts are vital for precise hardware selection, ensuring safety and efficiency in machinery. They simplify complex specifications, aiding in accurate installations and minimizing errors.

By adhering to these charts, professionals can maintain high standards of quality and reliability in their work, ensuring long-term durability and performance in various applications.

9.1 Best Practices for Using Machine Screw Charts

Always print charts to actual size to ensure accuracy and measure the ruler margin for scale verification. Use correct tap and clearance drills for specific materials, and consult torque specifications for proper installation. Refer to standards like ASME B 1.1 for thread dimensions and material compatibility. Regularly update charts and cross-reference with manufacturers’ data for reliability and performance.

9.2 Future Trends in Screw Technology

Future trends include the development of lightweight, corrosion-resistant materials and self-tapping screws for automation. Advances in smart manufacturing will integrate IoT for real-time monitoring, enhancing assembly efficiency and reducing errors.

Improved design software and 3D printing will enable custom screw solutions. Sustainable practices will drive eco-friendly materials and energy-efficient production, shaping the next generation of machine screw technology.

About the author