Differential systems are crucial mechanical components that enable vehicles to transmit power while allowing wheels to rotate at varying speeds‚ ensuring smooth operation and control.

1.1 Overview of Differential Function

The differential is a vital component that enables wheels to rotate at different speeds while maintaining traction and control; It consists of gears that work together to distribute power between wheels‚ ensuring smooth cornering and preventing skidding. This mechanism is essential for vehicle stability and performance‚ particularly during turns or uneven terrain conditions.

1.2 Importance of Differential in Vehicle Performance

The differential is essential for optimizing vehicle performance by enabling wheels to rotate at varying speeds during turns‚ enhancing maneuverability and traction. It ensures smooth power distribution‚ prevents skidding‚ and maintains stability. This component is critical for both on-road and off-road driving‚ directly impacting a vehicle’s overall handling‚ efficiency‚ and driver control.

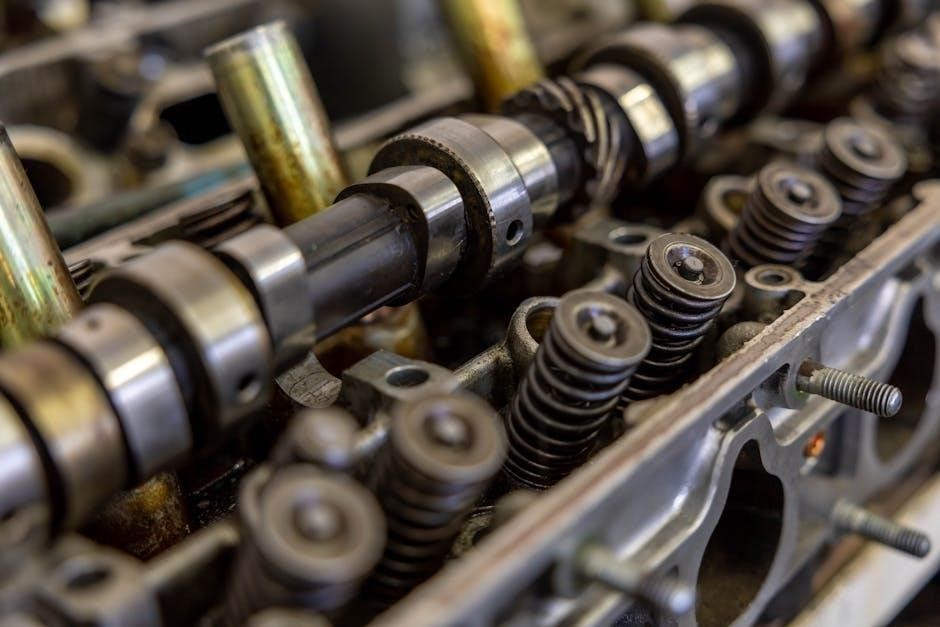

Major Parts of a Differential

A differential consists of key components like the ring gear‚ pinion gear‚ side gears‚ and differential case assembly‚ all working together to enable smooth power distribution and independent wheel rotation;

2.1 Ring Gear

The ring gear is the largest gear in the differential system‚ mounted on the differential case. It meshes with the pinion gear to transfer power from the driveshaft to the wheels. The ring gear’s teeth must be in perfect condition to ensure smooth engagement. Proper lubrication is essential to prevent overheating and wear. The ring gear is a critical component for efficient power transfer and differential operation.

2.2 Pinion Gear

The pinion gear is a smaller gear that meshes with the ring gear in the differential system. It plays a crucial role in transmitting power from the driveshaft to the differential case. Proper alignment and lubrication are essential for smooth operation. The pinion gear is a key component in enabling the differential to function effectively‚ ensuring power is distributed to the wheels efficiently.

2.3 Side Gears

Side gears are essential components of the differential system. They are attached to the axle shafts and rotate at different speeds‚ allowing the wheels to move independently. Proper lubrication and alignment ensure smooth operation‚ preventing wear and tear. The side gears work in conjunction with the pinion and ring gears to distribute power effectively during vehicle movement‚ enhancing traction and stability on various terrains. Regular maintenance ensures optimal performance and longevity of the differential system.

2.4 Differential Case Assembly

The differential case assembly houses the side gears and pinion gears‚ ensuring proper alignment and protection; It rotates with the ring gear during operation‚ enabling smooth power distribution. Lubrication is contained within the case‚ preventing contamination and wear. The assembly is crucial for maintaining gear integrity and facilitating independent wheel rotation‚ especially during turns‚ ensuring vehicle stability and performance on varying terrains.

Functions of the Differential

The differential enables wheels to rotate at different speeds‚ improving handling and preventing drag. It transfers power from the driveshaft to wheels‚ enhancing vehicle stability and performance.

3.1 Allowing Independent Wheel Rotation

The differential allows wheels to rotate independently‚ essential for smooth turning. When a vehicle turns‚ the outer wheel travels a longer path than the inner wheel. The differential gears enable the wheels to rotate at different speeds without skidding‚ improving handling and reducing tire wear. This function is critical for maintaining traction and stability during cornering or uneven terrain.

3.2 Transferring Power from Driveshaft to Wheels

The differential transfers power from the driveshaft to the wheels‚ ensuring smooth and efficient energy distribution. Through its gears‚ it directs torque to the wheels‚ enabling them to rotate at varying speeds. This mechanism is vital for maintaining stability and control‚ particularly during acceleration or cornering‚ where wheel speed variation is necessary for optimal vehicle performance and traction.

Types of Differentials

Differentials vary‚ with open types allowing independent wheel rotation and limited-slip improving traction by transferring power to wheels with grip‚ enhancing stability and control.

4.1 Open Differential

An open differential allows wheels to rotate independently‚ essential for smooth turns. It consists of spider gears‚ ring gear‚ and side gears. During straight driving‚ all gears align‚ but during turns‚ the spider gear rotates‚ enabling wheels to spin at different speeds. This setup is simple and cost-effective but lacks traction in low-grip conditions‚ where power may be sent to the wheel with less resistance.

4.2 Limited-Slip Differential

A limited-slip differential improves traction by transferring power to the wheel with more grip. It uses clutches or viscous fluids to limit wheel speed differences. Unlike open differentials‚ LSDs reduce slippage during cornering or low-traction conditions‚ enhancing stability and control. This design balances performance and everyday driving needs‚ offering better handling without sacrificing simplicity.

Maintenance and Repair Tips

Regular lubrication checks and inspections are essential for optimal performance. Addressing leaks promptly and ensuring proper gear alignment prevents wear and extends lifespan.

5.1 Service and Adjustment of Gears

Regular service involves inspecting gears for wear and ensuring proper lubrication. Adjustments may require shimming or replacing components to maintain correct backlash. Always follow manufacturer guidelines for precise alignment and smooth operation. Properly maintained gears enhance performance and extend the lifespan of the differential system.

5.2 Lubrication and Inspection

Proper lubrication ensures smooth gear operation‚ while regular inspections detect wear or damage. Check fluid levels and replace as needed. Inspect gears‚ bearings‚ and seals for signs of deterioration. Timely maintenance prevents costly repairs and ensures optimal performance of the differential system.

Differential Design Variations

Differential systems vary in design‚ including front and rear configurations‚ four-wheel drive setups‚ and axle assembly differences‚ each tailored for specific vehicle performance and operational needs.

6.1 Front vs. Rear Differential

The front differential‚ typically found in four-wheel-drive vehicles‚ distributes power to the front wheels‚ while the rear differential powers the rear wheels. Both components enable independent wheel rotation‚ ensuring optimal traction and control. However‚ their designs and applications differ based on vehicle type and drivetrain requirements‚ affecting overall performance and handling characteristics.

6.2 Four-Wheel Drive Differentials

Four-wheel drive differentials distribute power to all four wheels‚ enhancing traction and stability. They often include a transfer case to split power between front and rear axles. These systems use limited-slip or locking mechanisms to optimize torque distribution‚ improving performance on uneven or slippery surfaces. Advanced designs may incorporate electronic controls for dynamic adjustments‚ ensuring maximum grip and control in varying driving conditions.

PDF Guide to Differential Systems

A comprehensive PDF guide detailing differential components‚ functions‚ and maintenance procedures‚ offering a detailed overview for understanding and servicing differential systems effectively.

7.1 Components and Their Functions

The PDF guide outlines key differential components‚ including the ring gear‚ pinion gear‚ side gears‚ and differential case assembly. Each part plays a specific role in torque distribution and enabling independent wheel rotation‚ ensuring smooth power transfer and vehicle stability during various driving conditions.

7.2 Step-by-Step Maintenance Guide

Regular maintenance ensures optimal differential performance. Steps include checking lubrication levels‚ inspecting gears for wear‚ and replacing seals. Adjust backlash and ensure gasket integrity. Refer to the PDF guide for detailed procedures‚ torque specifications‚ and safety precautions to prevent damage and ensure precise adjustments.

Drive Axle Components

Drive axle components include the pinion gear‚ ring gear‚ side gears‚ and differential case assembly‚ essential for transferring power from the transmission to the vehicle’s wheels efficiently.

8.1 Rear Drive Axle Assembly

The rear drive axle assembly is a critical component that includes the differential‚ axle shafts‚ and bearings. It transfers power from the driveshaft to the wheels‚ enabling smooth rotation and torque distribution. The assembly ensures efficient energy transfer while allowing wheels to operate independently‚ enhancing vehicle stability and performance during various driving conditions.

8.2 Front Drive Axle Assembly

The front drive axle assembly is designed for vehicles with front-wheel drive or four-wheel drive systems. It includes components like CV joints‚ axle shafts‚ and bearings‚ enabling power delivery to the front wheels. This assembly works in conjunction with steering components‚ ensuring proper load distribution and smooth operation during acceleration and turning maneuvers‚ while maintaining vehicle stability and control.

Differential Case and Pinion Gear

The differential case houses the gears‚ while the pinion gear transfers power from the driveshaft to the ring gear‚ enabling torque distribution to the wheels efficiently;

9.1 Gear Ratio and Vehicle Performance

The gear ratio in a differential significantly impacts vehicle performance‚ affecting acceleration‚ speed‚ and torque delivery. A lower gear ratio enhances high-speed efficiency‚ while a higher ratio improves towing capacity and low-speed maneuverability. Proper gear ratio selection optimizes power distribution‚ ensuring balanced performance‚ efficiency‚ and traction‚ tailored to specific vehicle design and operational requirements.

9.2 Adjustments and Alignment

Proper adjustments and alignment of the differential case and pinion gear ensure optimal performance and prevent premature wear. Shims and backlash adjustments are critical for maintaining precise gear mesh. Misalignment can lead to noise‚ vibration‚ and reduced efficiency. Regular checks and precise alignment techniques are essential to sustain smooth operation and extend component lifespan.

Advanced Topics

Explore cutting-edge differential technologies‚ such as electronic torque vectoring and adaptive systems‚ and discover how custom upgrades enhance performance for specialized applications and extreme driving conditions.

10.1 Modern Differential Technologies

Modern differential technologies include advanced systems like electronic torque vectoring and adaptive differentials; These systems enhance traction and stability by dynamically distributing power between wheels. Active differentials‚ such as those with clutch packs‚ improve handling during cornering. Additionally‚ modern designs integrate with vehicle stability control systems‚ optimizing performance in various driving conditions while maintaining efficiency and durability. These innovations redefine how power is managed in contemporary vehicles;

10.2 Custom and Performance Upgrades

Custom and performance upgrades enhance differential efficiency‚ offering improved traction and stability. Aftermarket components like lightweight gear sets and high-strength axles optimize power delivery. Racing applications often utilize specialized lubricants and heat-treated gears for durability. Custom ring and pinion ratios can tailor torque and speed for specific needs. Performance clutches and limited-slip differentials further refine control and responsiveness in demanding conditions.

About the author