Guided rods are essential components in mechanical systems, providing precise linear motion and stability. They are widely used in automation, aerospace, and medical devices, ensuring smooth operation and accuracy in various applications. Their design incorporates advanced materials and alignment features, making them critical for modern machinery and equipment. Understanding their functionality and benefits is key to optimizing performance in industrial and technical environments.

1.1 Definition and Purpose

Guided rods are mechanical components designed to provide precise linear motion and stability in various applications. They typically consist of a rod and a guidance system, ensuring smooth and accurate movement. The primary purpose of guided rods is to maintain alignment and prevent deflection under load, making them essential in machinery, automation, and precision engineering. They are used to guide tools, parts, or mechanisms, ensuring consistent performance and reducing wear and tear. Their role is critical in applications requiring high accuracy and reliability.

1.2 Historical Background

Guided rods have evolved from early linear motion systems, with roots in the Industrial Revolution. Initially, simple mechanisms were used to guide machinery parts, but advancements in the mid-20th century introduced precision-engineered rods. The development of ball bearings and roller systems further enhanced their functionality. Historical innovations in materials and manufacturing processes have led to modern guided rods, which are integral to industrial automation, aerospace, and medical devices. Their evolution reflects the growing demand for precision and reliability in mechanical systems, making them a cornerstone of modern engineering.

Components of a Guided Rod System

A guided rod system consists of a rod, guidance mechanisms, and mounting features. These components work together to provide precise alignment and smooth linear motion in various applications.

2.1 Rod Material and Construction

Guided rods are typically made from high-strength materials like stainless steel, aluminum, or carbon fiber, ensuring durability and resistance to wear. The construction involves precise machining to maintain straightness and dimensional accuracy. Surface finishes and coatings may be applied to reduce friction and enhance performance. The choice of material depends on the application, with stainless steel offering corrosion resistance, aluminum providing lightweight durability, and carbon fiber delivering exceptional strength-to-weight ratios. Proper construction ensures smooth operation and longevity in various industrial and technical environments.

2.2 Guidance Mechanisms

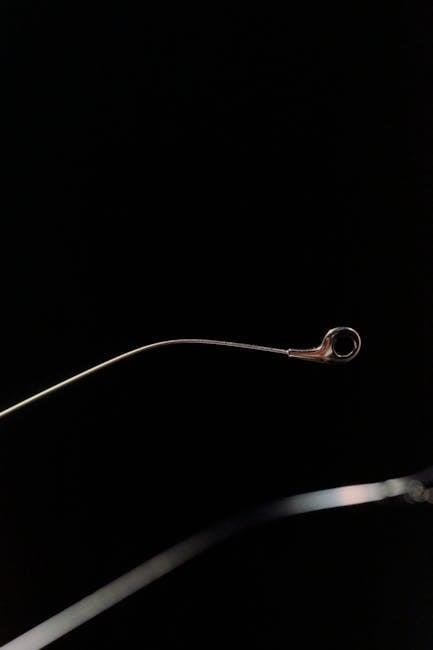

Guidance mechanisms in guided rod systems ensure precise alignment and smooth motion. These mechanisms often include bearings, bushings, or linear guides that allow the rod to move freely while maintaining stability. Some systems incorporate rollers or ball bearings to reduce friction and enhance accuracy. Advanced mechanisms may feature adjustable components to accommodate varying loads or environmental conditions. Properly designed guidance mechanisms are crucial for maintaining the integrity and performance of the rod system, ensuring reliable operation in demanding applications.

2.3 Mounting and Alignment Features

Mounting and alignment features are critical for ensuring guided rods function correctly. These components include brackets, clamps, and fasteners designed to secure the rod in place while maintaining precise alignment. Advanced systems often incorporate adjustable mounting points to accommodate varying installation requirements. Alignment features, such as guide pins or slots, help ensure proper positioning during setup; These elements are essential for achieving optimal performance, stability, and operational efficiency in applications where precise linear motion is required.

How Guided Rods Work

Guided rods operate by utilizing linear motion principles, incorporating guidance mechanisms and alignment features to ensure precise movement and stability in mechanical systems.

3.1 Principles of Operation

Guided rods function based on the principle of linear motion, where they enable smooth, controlled movement along a predefined path. Their operation relies on the interaction between the rod and guidance mechanisms, such as bearings or bushings, which minimize friction and ensure accuracy. The rod’s material properties, like rigidity and resistance to wear, play a crucial role in maintaining consistent performance. Proper alignment and lubrication further enhance their operational efficiency, making them indispensable in precision-driven applications across various industries.

3.2 Motion Control and Precision

Guided rods ensure high precision by maintaining consistent linear motion through advanced mechanical components. Their design incorporates features like bearings or slides, which minimize lateral movement and vibration. This allows for accurate positioning and smooth operation in applications requiring tight tolerances. The precision of guided rods is further enhanced by their material quality and alignment systems, ensuring reliable performance. These factors make them ideal for applications where exact control over movement is critical, such as in industrial automation and high-precision machinery.

Applications of Guided Rods

Guided rods are used in industrial automation, aerospace, and medical devices, ensuring precise motion control and reliability in demanding environments.

4.1 Industrial Automation

In industrial automation, guided rods play a crucial role in ensuring smooth and precise linear motion. They are integral to machinery such as CNC machines, robotic arms, and assembly lines, where consistent performance is vital. By providing stable guidance, these rods minimize wear and tear, reducing downtime and increasing overall efficiency. Their durability and resistance to environmental factors make them ideal for high-speed and heavy-duty applications, contributing to the reliability and productivity of modern manufacturing processes.

4.2 Aerospace Engineering

Guided rods are indispensable in aerospace engineering, ensuring precise movement and alignment in critical systems. They are used in aircraft landing gear, missile guidance, and satellite mechanisms, where accuracy and durability are paramount. High-strength materials like stainless steel and carbon fiber are often employed to withstand extreme conditions, such as temperature fluctuations and vibrations. These rods contribute to the reliability and performance of aerospace systems, making them essential for both military and commercial applications. Their role in maintaining operational efficiency and safety cannot be overstated.

4.3 Medical Devices

Guided rods play a crucial role in medical devices, where precision and reliability are vital. They are used in surgical instruments, patient handling equipment, and precise medical machinery. Their smooth motion and durability ensure accurate performance in procedures requiring minimal error margins. Stainless steel and carbon fiber rods are commonly used for their strength and resistance to corrosion. These components are essential in applications like minimally invasive surgery and rehabilitation equipment, enhancing patient care and operational efficiency. Their role in advancing medical technology highlights their importance in healthcare settings.

Choosing the Right Material

Material selection for guided rods is critical, impacting durability, weight, and performance. Stainless steel, aluminum, and carbon fiber are popular options, chosen based on application needs and environmental conditions;

5.1 Stainless Steel Rods

Stainless steel rods are a popular choice for guided rod systems due to their exceptional corrosion resistance, durability, and strength. They are ideal for harsh environments where moisture and chemicals are present. Their high resistance to wear and tear makes them suitable for heavy-duty applications. Stainless steel rods also offer excellent dimensional stability and can withstand extreme temperatures. This makes them a reliable option for industries requiring long-lasting performance and minimal maintenance. Their versatility and strength-to-weight ratio ensure they are widely used in industrial automation and machinery.

5.2 Aluminum Rods

Aluminum rods are lightweight, corrosion-resistant, and offer a high strength-to-weight ratio, making them ideal for applications requiring durability without excess weight. They are widely used in aerospace, automotive, and industrial automation due to their excellent thermal conductivity and resistance to environmental factors. Aluminum rods are also cost-effective and easy to fabricate, making them a popular choice for custom designs. Their versatility and performance make them suitable for high-performance systems and applications where weight reduction is critical. Aluminum rods are a reliable option for achieving precision and efficiency in guided rod systems.

5.3 Carbon Fiber Rods

Carbon fiber rods are renowned for their exceptional strength, stiffness, and lightweight properties, making them ideal for high-performance applications. They exhibit minimal thermal expansion and excellent resistance to fatigue, ensuring reliability in demanding environments. Commonly used in aerospace and industrial automation, these rods provide superior precision and durability. Their high strength-to-weight ratio allows for the design of compact and efficient systems. Carbon fiber rods are a premium choice when extreme performance and minimal weight are required, offering unmatched reliability and longevity in critical applications.

Installation and Alignment

Proper installation and alignment of guided rods are critical for optimal performance. Ensure the system is level and securely mounted to prevent misalignment. Use precision tools like lasers or alignment jigs for accurate setup. Mounting brackets should be tightened evenly to avoid warping. Regularly inspect the alignment to maintain operational efficiency and prevent wear. Misaligned rods can lead to premature failure, so careful installation is essential for long-term reliability and smooth operation in industrial and technical applications.

Maintenance and Repair

Regular maintenance is crucial to ensure guided rods function optimally. Inspect for wear, corrosion, or misalignment and clean surfaces to prevent contamination. Lubricate moving parts as recommended to reduce friction and extend lifespan. Replace damaged or worn components promptly to avoid system failure. Alignment checks should be performed periodically to maintain precision. Proper repair techniques and tools are essential to restore functionality without causing further damage. A well-maintained system ensures reliability, reduces downtime, and prolongs the operational life of guided rods in industrial and technical applications.

Safety Considerations

Ensuring safe operation and handling of guided rods is critical. Proper installation and maintenance are essential to prevent mechanical failure. Always follow manufacturer guidelines and use protective gear when working with guided rods. Avoid overloading, as this can lead to system malfunctions. Regularly inspect for wear or damage, and address issues promptly. Ensure all personnel are trained in safe operating procedures. Use appropriate safety equipment and follow industry standards to minimize risks and ensure a secure working environment with guided rod systems.

Comparison with Other Guidance Systems

Guided rods differ from other systems like linear bearings or bushings by offering precise alignment and stability. They excel in applications requiring high load capacity and durability. Unlike cam followers, guided rods are designed for linear motion without rotational constraints. Their ability to handle side loads and maintain accuracy makes them preferable in industrial automation. When compared to alternative systems, guided rods often provide longer service life and reduced friction, making them a reliable choice for demanding environments and high-precision tasks.

Future Trends in Guided Rod Technology

Future trends in guided rod technology include the use of lightweight, high-performance materials like carbon fiber and advanced alloys. Smart materials that adapt to environmental changes are also being explored. Innovations in surface coatings and self-lubricating designs aim to enhance durability and reduce maintenance. Modular and customizable rod systems are expected to gain popularity, allowing for tailored solutions in various industries. Additionally, advancements in additive manufacturing and integration with automation and IoT will drive precision and efficiency, making guided rods even more integral to modern machinery and applications.

Case Studies and Real-World Examples

Guided rods have proven essential in various industries, demonstrating their versatility and reliability. In manufacturing, they enable precise movements in CNC machines, reducing wear and tear. Aerospace applications utilize their durability in aircraft mechanisms. Medical devices rely on guided rods for accurate patient positioning in MRI machines. These examples highlight how guided rods enhance performance and efficiency, meeting specific demands across industries. Real-world applications showcase their adaptability and effectiveness in ensuring smooth, consistent operation in diverse environments.

About the author