Guide coat powder is a specialized coating material designed to detect surface imperfections during painting or finishing processes. It is applied as a thin‚ dry layer that adheres to surfaces‚ highlighting uneven areas‚ scratches‚ or dents. This innovative tool is widely used in automotive and industrial applications to ensure smooth finishes and optimal results.

1.1 Definition and Purpose

Guide coat powder is a fine‚ dry material applied to surfaces to detect imperfections like scratches or dents. Its purpose is to ensure surface quality by highlighting uneven areas‚ enabling precise sanding and smoothing. Widely used in automotive and industrial settings‚ it enhances finishing processes and guarantees a flawless final result.

1.2 Brief History and Development

Guide coat powder originated as a niche tool in surface finishing‚ evolving with advancements in powder coating technology. Initially used for detecting imperfections in metal surfaces‚ it gained popularity in automotive repair. The development of dry guide coats marked a significant milestone‚ offering convenience and effectiveness. Over time‚ its application expanded to industrial settings‚ driven by innovations in materials and manufacturing processes.

Key Characteristics of Guide Coat Powder

Guide coat powder is a specialized coating material designed to detect surface imperfections. It is available in dry or wet forms‚ ensuring compatibility with various systems. Its eco-friendly properties and versatility make it a preferred choice in automotive and industrial applications.

2.1 Composition and Types

Guide coat powders are typically made from fine‚ colored particles‚ often carbon-based or thermoplastic‚ designed to adhere lightly to surfaces. They come in dry and wet forms‚ with dry versions like carbon black powders being popular for their ease of use and effectiveness in detecting imperfections without requiring masking.

2.2 Advantages Over Traditional Methods

Guide coat powders offer superior efficiency and accuracy compared to traditional liquid or aerosol methods. They eliminate the need for masking‚ reduce waste‚ and provide immediate visual feedback. Dry guide coats‚ in particular‚ are mess-free and reusable‚ streamlining surface preparation and sanding processes while ensuring a smooth‚ even finish.

Application Process of Guide Coat Powder

Guide coat powder is applied as a thin‚ dry layer using specialized applicators‚ ensuring even coverage. It highlights imperfections instantly‚ streamlining surface preparation and sanding processes.

3.1 Surface Preparation Requirements

Surface preparation is critical for effective guide coat powder application. Ensure the area is clean‚ dry‚ and free of dust‚ oils‚ or grease. Primers or body fillers must be fully cured and sanded smooth. Any contaminants or moisture can hinder adhesion and detection accuracy. Proper preparation ensures the guide coat adheres evenly‚ highlighting imperfections clearly for precise sanding and finishing.

3.2 Step-by-Step Application Guide

Use the integrated applicator to apply the guide coat powder in a circular motion.

Ensure even coverage over the entire surface.

Allow the powder to settle briefly before sanding.

Sand the area until the guide coat is no longer visible.

Wipe clean with a tack cloth to inspect imperfections.

Repeat if necessary for optimal results.

3.4 Tools and Equipment Needed

The application of guide coat powder requires specific tools for optimal results. A flexible-edge applicator ensures even coverage on contoured surfaces. Sanding tools‚ such as block sanders or orbital sanders‚ are essential for smoothing the surface. A tack cloth is used to wipe away residue post-sanding. Additional tools like a vacuum cleaner for dust removal and a light source for inspection may also be beneficial.

Types of Guide Coat Powder

Guide coat powders are available in dry and wet forms‚ with colored options like blue for enhanced visibility. They cater to different surface types and applications‚ ensuring versatility.

4.1 Dry vs. Wet Guide Coats

Dry guide coats are fine‚ colored powders applied without moisture‚ ideal for detecting surface imperfections on primers or body fillers. Wet guide coats‚ applied as liquids‚ offer smooth coverage but require masking. Dry versions are more versatile‚ especially for contoured areas‚ and eliminate the need for masking‚ streamlining the sanding process.

4.2 Colored vs. Black Guide Coats

Colored guide coats offer enhanced visibility‚ making imperfections like scratches or pinholes more apparent during sanding. Black guide coats‚ often carbon-based‚ provide contrast on lighter surfaces. Both types aid in detecting flaws‚ but colored versions are preferred for their vibrant contrast‚ while black coats are ideal for specific applications requiring a more subtle appearance.

Detecting Surface Imperfections

Guide coat powder is a thin‚ dry layer applied to surfaces to highlight imperfections like scratches or dents‚ ensuring smooth finishes.

5.1 Common Defects Identified

Guide coat powder effectively identifies common surface imperfections such as deep scratches‚ pinholes‚ and uneven areas. It highlights these defects by adhering to the surface‚ making them visible during sanding or finishing processes. This ensures a smooth‚ even finish by allowing precise identification and correction of flaws before final coating applications.

5.2 How Guide Coat Powder Highlights Issues

Guide coat powder highlights surface imperfections by adhering to low spots and scratches‚ creating contrast during sanding. As the powder is sanded away‚ areas with defects remain visible‚ allowing precise identification and correction. This visual aid ensures a smooth finish by revealing uneven surfaces‚ pinholes‚ and other flaws that might otherwise go unnoticed.

Guide Coat Powder in Automotive and Industrial Applications

Guide coat powder enhances surface preparation and defect detection in automotive and industrial applications‚ ensuring smooth finishes and optimal results in metal and aluminum refinishing processes.

6.1 Use in Automotive Repair and Refinishing

Guide coat powder is extensively used in automotive repair to detect surface imperfections like scratches and dents. It is applied over primers or fillers‚ highlighting uneven areas during sanding. This ensures a smooth finish before painting‚ reducing rework and improving overall quality in collision repair and refinishing processes.

6.2 Industrial Uses for Metal and Aluminum

Guide coat powder is widely used in industrial metal and aluminum processing to identify surface defects like pinholes or scratches. It ensures smooth finishes before final coating‚ enhancing durability and corrosion resistance. Its eco-friendly properties and versatility in wet or dry applications make it ideal for large-scale operations‚ reducing defects and improving efficiency in industrial settings.

Comparison with Other Guide Coats

Guide coat powder is a dry‚ efficient solution for detecting surface imperfections without masking‚ offering advantages over liquid and aerosol guide coats‚ especially on metals in various industrial settings.

7.1 Liquid vs. Aerosol vs. Powder Guide Coats

Liquid guide coats are applied wet‚ offering precise coverage but requiring masking. Aerosol guide coats combine ease of use with quick drying. Powder guide coats‚ like dry versions‚ eliminate masking and provide consistent results‚ making them ideal for automotive and industrial applications. Each method offers unique advantages‚ with powders excelling in efficiency and ease of use for detecting imperfections during sanding.

7.2 Cost and Efficiency Analysis

Powder guide coats are cost-effective‚ reducing material waste and labor costs. They eliminate masking requirements‚ saving time and effort. With faster curing times and lower energy consumption‚ powders offer economic advantages. Their efficiency in highlighting imperfections ensures high-quality finishes‚ making them a valuable investment for automotive and industrial applications seeking long-term cost savings and productivity gains.

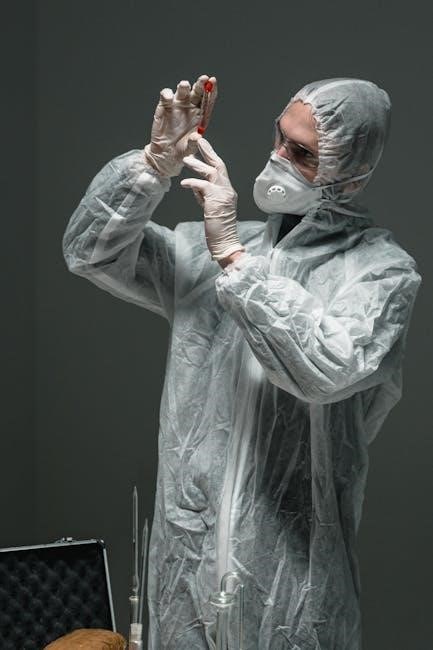

Safety and Health Considerations

Proper handling and storage of guide coat powder are essential. Inhaling fine particles poses health risks‚ so respiratory protection is recommended. Use in well-ventilated areas and avoid skin contact to ensure safety.

8.1 Proper Handling and Storage

Handle guide coat powder in a well-ventilated area‚ avoiding inhalation of fine particles. Wear protective gear‚ including gloves and a dust mask. Store in a cool‚ dry place away from direct sunlight and moisture. Keep containers tightly sealed when not in use to prevent contamination and ensure longevity. Follow manufacturer guidelines for safe handling practices.

8.2 Health Risks and Protective Measures

Inhaling guide coat powder can pose respiratory risks‚ so wear a dust mask or respirator. Prolonged exposure may cause irritation; avoid skin contact. Use safety glasses and gloves to protect against particle exposure. Work in well-ventilated areas to minimize dust inhalation. Follow safety guidelines to prevent health issues and ensure safe handling of the powder.

Environmental Impact

Guide coat powder offers eco-friendly properties‚ reducing hazardous waste. It contains no VOCs‚ making it a more environmentally friendly option. Proper disposal ensures minimal environmental impact.

9.1 Eco-Friendly Properties

Guide coat powder is eco-friendly‚ containing no hazardous waste during manufacture or application. It is non-toxic‚ biodegradable‚ and emits no VOCs‚ making it a sustainable choice. Proper disposal further minimizes environmental impact‚ aligning with green practices.

9.2 Waste Management and Disposal

Guide coat powder waste should be disposed of according to local regulations. It is non-toxic and does not generate hazardous waste‚ making it environmentally safe. Proper disposal methods ensure minimal ecological impact‚ aligning with sustainable practices. Always follow recommended guidelines for handling and discarding leftover powder to maintain environmental safety.

Popular Brands and Products

Popular brands include 3M Guide Coat‚ Farecla Guide Coat‚ and U-POL Aerosol Guide Coat‚ each known for their high-quality‚ efficient solutions in detecting surface imperfections.

10.1 3M Guide Coat

3M Guide Coat is a premium product designed for surface preparation‚ offering excellent imperfection detection. It is available in dry and aerosol forms‚ ensuring versatility for various applications. Known for its ease of use‚ 3M Guide Coat helps achieve smooth finishes in automotive and industrial settings‚ making it a trusted choice among professionals.

10.2 Farecla Guide Coat

Farecla Guide Coat is a reliable tool for detecting surface imperfections‚ offering precision in automotive and industrial applications. Its fine‚ colored powder adheres evenly‚ highlighting scratches and pinholes on primers or body fillers. Easy to apply with an integrated applicator‚ it ensures smooth sanding and finishing processes‚ making it a favorite among professionals for achieving flawless results.

10.3 U-POL Aerosol Guide Coat

U-POL Aerosol Guide Coat offers a convenient and efficient solution for detecting surface imperfections. Its aerosol formulation ensures easy application‚ providing a thin‚ even layer that highlights scratches‚ pinholes‚ and uneven areas on primers or body fillers; Ideal for automotive repair‚ it is compatible with various refinish systems‚ streamlining the sanding and finishing process for professional results.

Troubleshooting Common Issues

Troubleshooting guide coat powder issues involves identifying common problems like uneven application or ineffective imperfection detection and resolving them through proper techniques or reapplication as needed for optimal results.

11.1 Uneven Application

Uneven application of guide coat powder can occur due to improper technique‚ insufficient powder‚ or surface irregularities. To resolve this‚ ensure smooth‚ consistent strokes with the applicator. For contoured areas‚ use the flexible edges of the applicator to maintain even coverage. If unevenness persists‚ lightly reapply the powder and sand thoroughly. This ensures a uniform base for detecting imperfections effectively.

11.2 Ineffective Imperfection Detection

Ineffective imperfection detection can occur if the guide coat powder is applied too lightly or unevenly‚ failing to highlight defects. To address this‚ ensure proper powder coverage and use a light mist application. Reapply if necessary‚ and inspect under good lighting. Specialized tools‚ like applicators with flexible edges‚ can improve detection accuracy on contoured surfaces‚ ensuring all imperfections are identified clearly.

Market Trends and Future Developments

The market is evolving with advancements in powder technology‚ offering low curing temperatures and cost efficiency. Growing demand across industries drives innovation and eco-friendly solutions.

12.1 Innovations in Powder Coating Technology

Innovations in powder coating technology include advancements in thermal properties‚ enabling lower curing temperatures for heat-sensitive substrates. Eco-friendly solutions‚ such as zero hazardous waste production‚ are gaining traction. These developments enhance efficiency‚ reduce costs‚ and expand applications across automotive‚ industrial‚ and manufacturing sectors‚ driving sustainable growth and meeting evolving industry demands.

12.2 Growing Demand in Various Industries

The demand for guide coat powder is increasing across industries due to its effectiveness in detecting surface imperfections. Automotive repair shops use it for collision repair and refinishing. Metal fabricators and industrial manufacturers also adopt it for ensuring smooth finishes. The rise in industrial applications and the need for high-quality surfaces drive its growing popularity and market expansion.

About the author